A microlens is a very small lens. In general, these lenses have a diameter of less than one millimeter and are usually as small as 10 micrometers. Originally, they were fabricated for use in microscopes in the 17th century. While micro lens arrays are still used for microscopes these days, they have become commonly used for a lot of other applications like photocopiers, cell phone cameras, and 3D displays.

Kinds of Microlens

A typical microlens has one plane surface and one spherical convex surface for refracting light. Due to the small size of these lenses, the underlying layer called substrate is often thicker. Such extra thickness must be taken into account in the design. For more sophisticated lenses, aspherical surfaces are utilized. Others may use many layers of optical material to reach a higher performance level.

Moreover, a microlens can also have two parallel flat planes and the different refractive index across them cause the act of focusing. Some lenses attain focus action by utilizing both a variation in the refractive index and the surface shape. The lens called Micro-Fresnal focuses light by retracting it with a set of concentric curved surfaces. They can be fabricated to be quite thin and lightweight.

Formation of Microlens Arrays

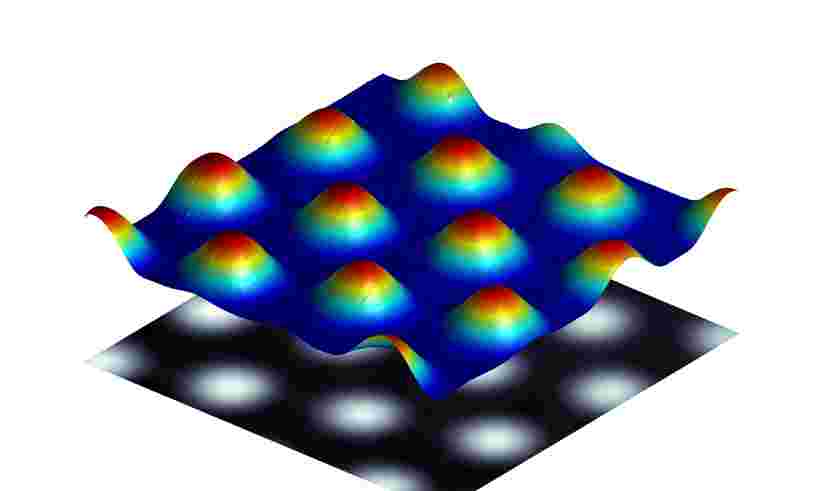

Microlens arrays have several microlenses formed in either a one-dimensional or two-dimensional array on a supporting substrate. The lenses have circular apertures and are arranged hexagonally to reach maximum coverage of the substrate. Although gaps exist between lenses, they can be reduced by making the lenses with non-circular apertures. When it comes to optical sensor arrays, the tiny lens systems focus and the light onto the photodiode surface to prevent it from landing on non-photosensitive areas of the pixel device.

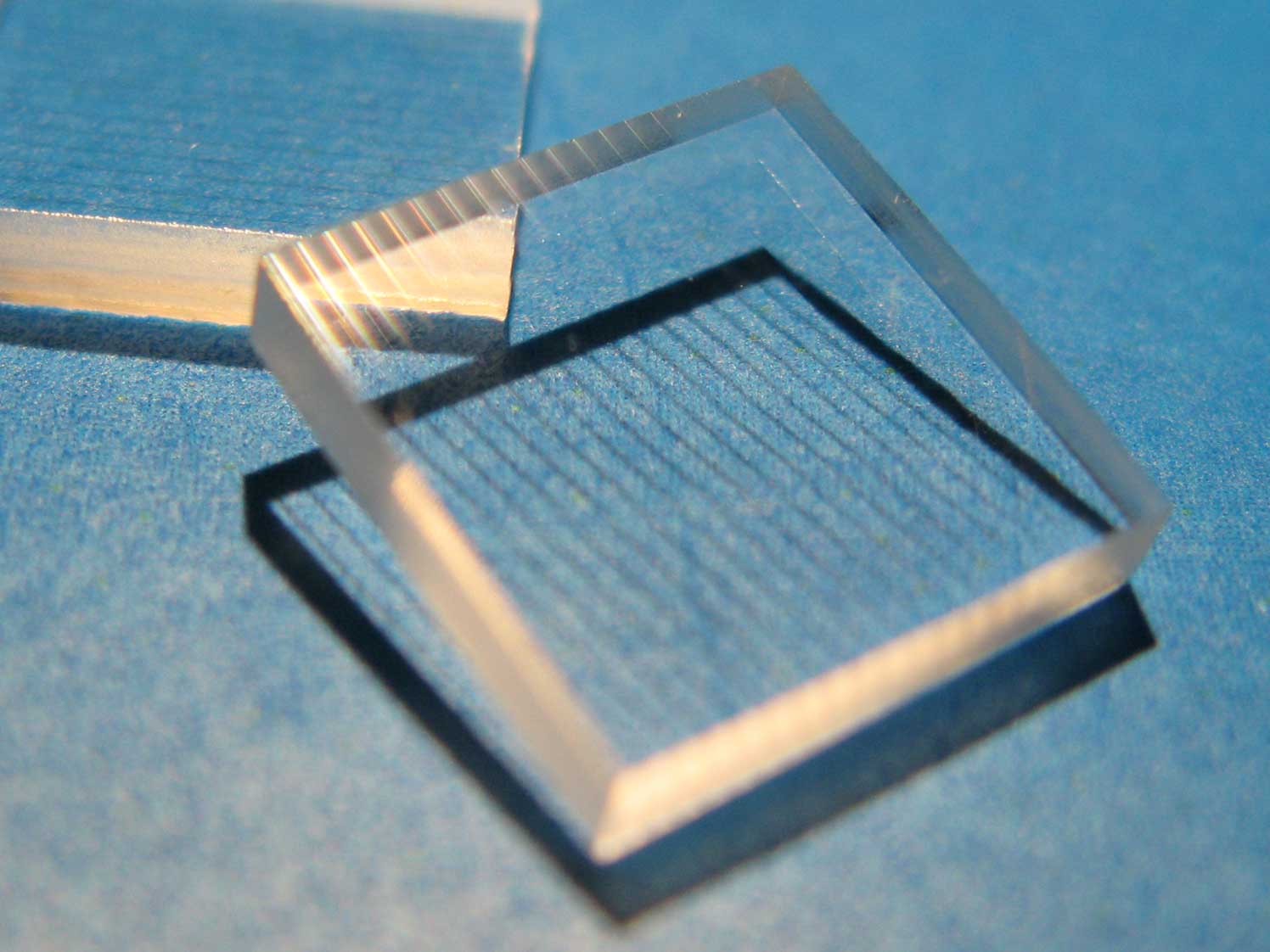

Before, small glass lenses were made by melting small filaments of Venetian glass and allowing the surface tension in the molten glass to form the smooth spherical surface required. In modern times, the arrays can be made using the convective assembly of colloidal particles from suspension.

These days, microlenses are designed and fabricated to close tolerance using different methods. In general, the process requires multiple copies formed by molding or embossing using a master lens array. The tiny lenses can be fabricated from liquids. An ultrafast laser 3D nanolithography technique is used for making a glass-like, free-form microlens. This is ideal for high power and harsh environment applications. Also, bio-microlenses have been made to photograph biological specimens without causing damage. They can be made by attaching a single cell t a fiber probe.